Posts

Showing posts from 2018

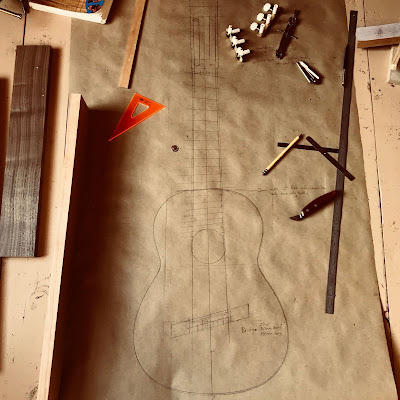

On the Workbench - Redwood/Curly Walnut Hernandez y Aguado Style Guitar, Part 1

- Get link

- X

- Other Apps

The Best Ingredients for a Fine Wood Finish

- Get link

- X

- Other Apps

Building an Eight String "Brahms" Classical Guitar, Part One

- Get link

- X

- Other Apps

An Unorthodox Nicholson-Style Workbench

- Get link

- X

- Other Apps

Want to Hear What a Wilson Burnham Guitar Sounds Like?

- Get link

- X

- Other Apps

SOLD! 2017 Redwood/East Indian Rosewood Classical Guitar

- Get link

- X

- Other Apps

The Impractical Guitar Maker - Why I Make Guitars, Part One

- Get link

- X

- Other Apps