Posts

Showing posts from 2017

The Impractical Guitar Maker - Wedged Joints

- Get link

- X

- Other Apps

Capos/Cejillas - New Batch of Six Padauk Wood Capos!

- Get link

- X

- Other Apps

Ten Years of Blogging - A Couple of Thoughts

- Get link

- X

- Other Apps

Starting a Classical Guitar Rosette Design

- Get link

- X

- Other Apps

The Guitar Maker's Backsaw for Cutting Fret Slots

- Get link

- X

- Other Apps

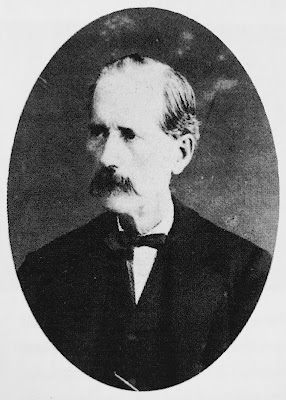

Antonio de Torres - Guitar Maker, Carpenter

- Get link

- X

- Other Apps

1961 Hernandez y Aguado Style Guitar, Engelmann Spruce/Ziricote, Nearing Completion

- Get link

- X

- Other Apps