Posts

Showing posts from 2021

Double Top Classical Guitar - Redwood/Nomex/Sitka Spruce/Curly Black Walnut, Part 1

- Get link

- X

- Other Apps

Building an 1830's René Lacôte "Legnani Model" Guitar

- Get link

- X

- Other Apps

European Spruce/Canada Cypress Classical Guitar

- Get link

- X

- Other Apps

Classical Guitar Festival Experiences, Part 2

- Get link

- X

- Other Apps

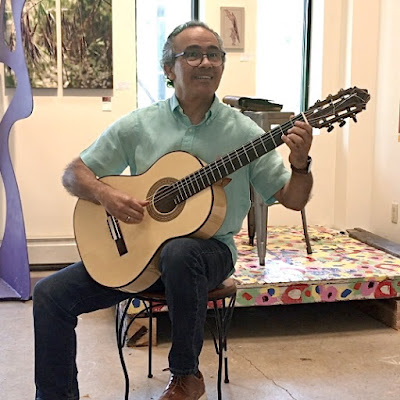

What a Concert Classical Guitarist Says About My Guitars

- Get link

- X

- Other Apps

Classical Guitar Festival Experiences , Part 1

- Get link

- X

- Other Apps

European Spruce/Canadian Cypress Grand Concert Classical Guitar, Available at Savage Classical Guitar 11/11/24

- Get link

- X

- Other Apps

Basic Tool Kit for Making a Classical Guitar - Another Look

- Get link

- X

- Other Apps

Shaping a Classical Guitar Neck - My Latest Concert Grand Guitar

- Get link

- X

- Other Apps

Moving Day - From a Small Shop to a Tiny Shop

- Get link

- X

- Other Apps