Facing up, or “taking out of wind”, is the producing of a practically true surface upon a piece of wood so that every part lies, in the same plane.

George Ellis, Modern Practical Joinery, 1902

I don’t remember when I purchased this back and side set of palo escrito, maybe twelve or fifteen years ago, when Luthiers Mercantile decided that they could no longer offer that wood for sale, their buyers were having problems finding palo escrito that was legally harvested. I thought I would get a set and see what kind of guitar it would make.

When the tone wood arrived, I unpacked the back and sides, stickered everything, put weights on it and placed it in the closet space under the roof of the house. One month later I pulled out the wood and discovered that the back wood was badly cupped, the sides were still nice and straight and flat.

I was a little horrified by what I found.

There was no way I was going to be able to flatten this with just a hand plane and I didn’t know anyone who owned a high end drum sander (I still don’t). I wetted the inside of the cupping with water and heated the other side with a heat gun, that didn’t work, then I tried to iron it flat with an old clothes iron at the highest setting, that didn’t work either but there was a wonderful rosewood aroma in the shop for a while.

Frustrated, I put the wood away hoping at some point I would find a solution.

Several years ago, I became aware of

Roarockit, a company that sold vinyl vacuum bags made just for luthiers, and bought their Thin Air Press (TAP) luthier bags. I have used them to laminate guitar sides and veneers, glue on sound board grafts, and other tasks to with great success.

I knew that laminating the backs with a veneer could solve the problem of cupping.

Earlier this month, I put my plan into action.

I chose an Engelmann spruce top that had a great tap tone…

…applied a thin coat of polyurethane glue…

…mated it to its corresponding piece of palo escrito, placed it in the TAP bag, pumped all the air out and waited for twenty four hours before removing the pieces from the bag. I did this for both pieces.

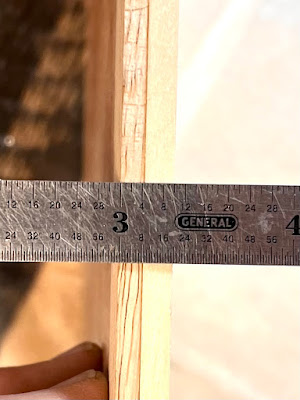

And the result, a board that is flat and one that I can “take out of wind”. One thing I need to mention is that I did not sand the gluing surface of the palo escrito, I worked under the assumption that the polyurethane glue would gap fill any irregularities. I did lightly sand the gluing surface of the spruce and followed the glue manufacturer’s instructions.

There is plenty of wood to work with and the back pieces ring like a bell when I tap them!

Next year, I will make a classical guitar from this wood and if I like the sonic capabilities of palo escrito, I may look for another set that was legally harvested.

It’s going to be a very pretty guitar!

Comments

Post a Comment