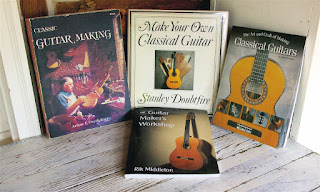

Four Good Books to Read on Classical Guitar Making

The chequered bark is unique, and its resemblance to a saurian hide has well earned for it the name of Alligator Juniper. So apt is the description that if you have ever heard of the existence of such a tree you identify it upon your first sight of it.

Donald Culross Peattie, A Natural History of Western Trees, 1950

Four books to read if you are interested in making a classical guitar.

Guitarmaking, by Art Overholtzer. This is not the book to use to make a classical guitar, you'd get stuck half way through and then you'd have to figure out on your own how to finish it. Overholtzer has some different ideas about guitar making, and like Bogdanovich, if you have a shop full of big huge metal or woodworking machines you can make the Overholtzer guitar. Read it for Art's opinions on wood and sound production.

Make Your Own Classical Guitar, by Stanley Doubtfire. Another book that shows you a wacky way to build a guitar. Some very interesting techniques and several good hand tools that every aspiring luthier should have in his/her tool box/cabinet. The biggest plus about the book are the interviews that Doubtfire did with the Fleta Brothers, Jose Romanillos and Robert Bouchet. If you can find a copy be ready to shell out some big bucks, it is quite collectible.

The Art and Craft of Making Classical Guitar, by Manuel Rodriguez. Not so much a how to box like the previous ones, but Rodriguez wrote a book very much like Jose Ramirez III did with Things About the Guitar. He gives us a wonderful history about some of the great Spanish makers and alludes to what the guitar means to a Spanish maker. Definitely a must have for the book shelf.

The Guitar Maker's Workshop, by Rik Middleton. Bottom line on this book: if you can get a copy of Cumpiano's book, Courtnell's book and this one by Middleton, you can build a guitar! Quirky and wacky like his predecessor, Stanley Doubtfire, this is a very English way of making a guitar. He has some great ideas for a home shop with little in the way of power tools, hand made clamps, bending iron, using bubble wrap on your bench to protect the guitar, some wonderful pointers. It's not the Spanish way of constructing a guitar, but it works. The best thing about this book is his little chapter that discusses neck relief, it's the only book in print that is widely available that talks about it. He is very much in line with Eugene Clark's definition of neck relief as presented in his 2004 Guild of American Luthiers presentation. Buy it for that!

As always, little buckaroos, remember-Hand tools rule the school!

Donald Culross Peattie, A Natural History of Western Trees, 1950

Four books to read if you are interested in making a classical guitar.

Guitarmaking, by Art Overholtzer. This is not the book to use to make a classical guitar, you'd get stuck half way through and then you'd have to figure out on your own how to finish it. Overholtzer has some different ideas about guitar making, and like Bogdanovich, if you have a shop full of big huge metal or woodworking machines you can make the Overholtzer guitar. Read it for Art's opinions on wood and sound production.

Make Your Own Classical Guitar, by Stanley Doubtfire. Another book that shows you a wacky way to build a guitar. Some very interesting techniques and several good hand tools that every aspiring luthier should have in his/her tool box/cabinet. The biggest plus about the book are the interviews that Doubtfire did with the Fleta Brothers, Jose Romanillos and Robert Bouchet. If you can find a copy be ready to shell out some big bucks, it is quite collectible.

The Art and Craft of Making Classical Guitar, by Manuel Rodriguez. Not so much a how to box like the previous ones, but Rodriguez wrote a book very much like Jose Ramirez III did with Things About the Guitar. He gives us a wonderful history about some of the great Spanish makers and alludes to what the guitar means to a Spanish maker. Definitely a must have for the book shelf.

The Guitar Maker's Workshop, by Rik Middleton. Bottom line on this book: if you can get a copy of Cumpiano's book, Courtnell's book and this one by Middleton, you can build a guitar! Quirky and wacky like his predecessor, Stanley Doubtfire, this is a very English way of making a guitar. He has some great ideas for a home shop with little in the way of power tools, hand made clamps, bending iron, using bubble wrap on your bench to protect the guitar, some wonderful pointers. It's not the Spanish way of constructing a guitar, but it works. The best thing about this book is his little chapter that discusses neck relief, it's the only book in print that is widely available that talks about it. He is very much in line with Eugene Clark's definition of neck relief as presented in his 2004 Guild of American Luthiers presentation. Buy it for that!

As always, little buckaroos, remember-Hand tools rule the school!

somewhere in my office I have an oddball English how-to book, published in the 50s or early 60s. The thrust of the book was steel-string spanish guitar construction but the advice was good--the author was, I recall, repair shop boss for one of the big London music stores. Not much romance-of-the-wood-and-song-of-the-box-plane to it, just straight from the shoulder advice on how to do the job. Wish I could find it....

ReplyDeletethat sapele plank is calling to me. Can't resaw until Tuesday, though. will send pictures as the project develops!