Krenov-Style Scraping Plane, Part 1

...the only way to obtain one is to make one.

Bernard S. Mason, Woodcraft, 1973

The flooding in my part of Colorado is over, but the destruction left behind by the flood waters is something that we will have to deal with for years. Colorado State Highway 7, which I drove to get to my job in Longmont, is only sort of there, 50 percent of the road is gone! Fortunately we do have a way to get to Boulder, down Gold Hill Road to Sunshine Canyon, the only problem with that is it is a steep and bumpy dirt road with a 25mph speed limit. It takes me an hour and a half to get to work this way, it triples my commute time!

Aside from all of that, my wife and I are very grateful that we have a house, our hearts go out to those who lost their houses or are unable to reach them. It will take time to recover and to get back to a "normal" way of life.

This scraper plane is something I was working on before all the chaos.

I decided to make a Krenov-style scraping plane to help smooth guitar sides and help with the final dimensioning of said pieces of wood. Using Dave Finck's book on plane making, click here for his website, I started to make one.

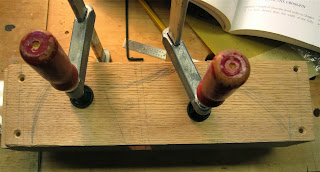

I found a nice piece of red oak at the Woodcraft Store in Loveland, Colorado, it's heavy and had a wonderful ring tone when I tapped the blank against the concrete floor in the store. In this photo, all the parts have been cut with a table saw and dimensioned with a hand plane and a sanding board. I've clamped it all together.

I didn't have much success using dowels to hold the parts together before glue up, my drill press has enough quill runout that the bit makes a hole ever so bigger than the dowel. Or is the dowel ever so smaller than the hole? I got out my battery powered drill and screwed the sides to the body blocks. Oh, so much easier!

Making the cross pin with just a sloyd knife is easy, make sure that the piece is square, make center marks on both ends making sure that all lines are parallel to those points, draw a circle of appropriate size on the ends and start carving away the wood that doesn't look round. This piece fit like a dream and was parallel to bed of the plane.

With the cross pin in place it was time for the "glue up".

I discovered that the blade in my bow saw is dull, well, I did make the blade out of a bandsaw blade that I bought at Wal-Mart twenty some years ago. I need to buy another bandsaw blade, it sure is hard sawing this piece of kiln-dried oak!

Here is where I am at, I need to make the wedge to hold the plane iron in place. That is the problem with having a regular day job, it is hard to make time for the projects you really want to do.

Happy first day of Fall!

Bernard S. Mason, Woodcraft, 1973

The flooding in my part of Colorado is over, but the destruction left behind by the flood waters is something that we will have to deal with for years. Colorado State Highway 7, which I drove to get to my job in Longmont, is only sort of there, 50 percent of the road is gone! Fortunately we do have a way to get to Boulder, down Gold Hill Road to Sunshine Canyon, the only problem with that is it is a steep and bumpy dirt road with a 25mph speed limit. It takes me an hour and a half to get to work this way, it triples my commute time!

Aside from all of that, my wife and I are very grateful that we have a house, our hearts go out to those who lost their houses or are unable to reach them. It will take time to recover and to get back to a "normal" way of life.

This scraper plane is something I was working on before all the chaos.

I decided to make a Krenov-style scraping plane to help smooth guitar sides and help with the final dimensioning of said pieces of wood. Using Dave Finck's book on plane making, click here for his website, I started to make one.

I found a nice piece of red oak at the Woodcraft Store in Loveland, Colorado, it's heavy and had a wonderful ring tone when I tapped the blank against the concrete floor in the store. In this photo, all the parts have been cut with a table saw and dimensioned with a hand plane and a sanding board. I've clamped it all together.

I didn't have much success using dowels to hold the parts together before glue up, my drill press has enough quill runout that the bit makes a hole ever so bigger than the dowel. Or is the dowel ever so smaller than the hole? I got out my battery powered drill and screwed the sides to the body blocks. Oh, so much easier!

Making the cross pin with just a sloyd knife is easy, make sure that the piece is square, make center marks on both ends making sure that all lines are parallel to those points, draw a circle of appropriate size on the ends and start carving away the wood that doesn't look round. This piece fit like a dream and was parallel to bed of the plane.

With the cross pin in place it was time for the "glue up".

I discovered that the blade in my bow saw is dull, well, I did make the blade out of a bandsaw blade that I bought at Wal-Mart twenty some years ago. I need to buy another bandsaw blade, it sure is hard sawing this piece of kiln-dried oak!

Here is where I am at, I need to make the wedge to hold the plane iron in place. That is the problem with having a regular day job, it is hard to make time for the projects you really want to do.

Happy first day of Fall!

Comments

Post a Comment