My French Polishing Technique Has Taken On An English Air...

French polish can, of course, be perfectly successful as a finish.

Charles H. Hayward, Staining and Polishing, 1946

I am always tweaking my French polishing technique.

After working six-seven months out of the year as a historic preservation carpenter, I pretty much have to re-learn how to French polish when I get back into my shop. It is something I have to keep working at all the time.

I have and do experiment with techniques espoused by different authors on the subject, I still think that Ron Fernandez's video on French polish is one of the best, but often times what works for one person doesn't work for me.

Here are a few things that have worked for me:

Pumice, alcohol and a little bit of shellac make a great filler. Coating the wood first with egg white makes the filler a little bit harder. I no longer use any "synthetic" wood filler.

Olive oil works best for me, I haven't had much success with mineral oil.

Patience is the best ingredient for a successful finish.

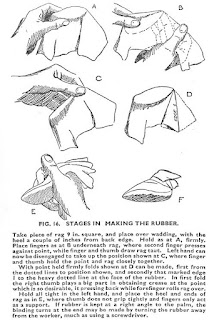

I recently changed how I make my pad (muneca, tampon, rubber, whatever you want to call it).

I make the way the great Charles H. Hayward describes it in his book, Staining and Polishing.

This is the English air that I mentioned in the title of this post.

The nice thing about a pad that is shaped like a mouse, it is easier to get shellac onto the surfaces where the guitar neck joins the body.

Hayward's book is a treasury of finishing techniques, I think everyone should take a look at it.

It reminds me of Paul Hasluck's book on wood finishing, Hayward's writing style, however, is much more matter-of-fact and easier to read.

If you are interested in learning how to French polish, I suggest that you read what books you can and view what videos you can find.

Then get yourself to your work bench and do it.

And remember, there is no miracle varnish/shellac/polyurethane/et cetera finish that can be applied and completed in one day.

If you do know of such a miracle finish and looks as good as shellac, please, let me know!

Charles H. Hayward, Staining and Polishing, 1946

I am always tweaking my French polishing technique.

After working six-seven months out of the year as a historic preservation carpenter, I pretty much have to re-learn how to French polish when I get back into my shop. It is something I have to keep working at all the time.

I have and do experiment with techniques espoused by different authors on the subject, I still think that Ron Fernandez's video on French polish is one of the best, but often times what works for one person doesn't work for me.

Here are a few things that have worked for me:

Pumice, alcohol and a little bit of shellac make a great filler. Coating the wood first with egg white makes the filler a little bit harder. I no longer use any "synthetic" wood filler.

Olive oil works best for me, I haven't had much success with mineral oil.

Patience is the best ingredient for a successful finish.

I recently changed how I make my pad (muneca, tampon, rubber, whatever you want to call it).

I make the way the great Charles H. Hayward describes it in his book, Staining and Polishing.

This is the English air that I mentioned in the title of this post.

The nice thing about a pad that is shaped like a mouse, it is easier to get shellac onto the surfaces where the guitar neck joins the body.

Hayward's book is a treasury of finishing techniques, I think everyone should take a look at it.

It reminds me of Paul Hasluck's book on wood finishing, Hayward's writing style, however, is much more matter-of-fact and easier to read.

If you are interested in learning how to French polish, I suggest that you read what books you can and view what videos you can find.

Then get yourself to your work bench and do it.

And remember, there is no miracle varnish/shellac/polyurethane/et cetera finish that can be applied and completed in one day.

If you do know of such a miracle finish and looks as good as shellac, please, let me know!

Enjoy reding your blog.

ReplyDeleteOnly finish that looks as great as shellac and can be finished in a day is soap finish. Quite common in Scandinavia. Leaves a nice, almost colorless, matte or silky finish that is soft to the touch.