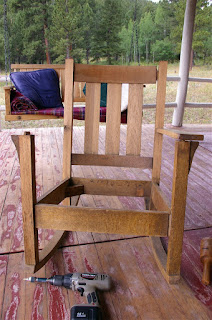

Restoring a Craftsman Style Rocking Chair, Part 1

An unimaginative person can neither be reverent or kind.

John Ruskin

He told me about how it was to be a boy in 1910, in the mountains there in northeastern California, hunting, fishing, trapping first and then how he became an old school buckaroo before he submitted to alcohol. I sat in this rocker when I was a teenager there in my great uncle's house in Red Bluff, California listening to the stories that rolled from him. When he died this rocker went into the attic of the barn at our place in Paynes Creek and sat there for 20 years before my wife pulled it down and placed it in the house.

Now here in Colorado, I decided that my wife was right, it was time to restore this old rocker. It didn't creak when you sat in it, it was a little rough around the edges and gray from the break down of the lignin in the oak. I gently pulled on an arm which came up with no resistance...

Then I pulled a little on the post and the rail came away from the joint...

...then the whole chair fell apart on its own. From those years sitting in a barn attic the hide glue in all the joints failed from the moisture in the winter and the searing heat from the roof in the summer.

The first thing that I did was to use a card scraper to remove what was left of the patina and old finish to get back down to the original wood. That took several evenings after work to complete and then I attacked the old mortises and tenons to clean out the old glue and to make sure all joints fitted tight.

More on the restoration in Part 2!

John Ruskin

He told me about how it was to be a boy in 1910, in the mountains there in northeastern California, hunting, fishing, trapping first and then how he became an old school buckaroo before he submitted to alcohol. I sat in this rocker when I was a teenager there in my great uncle's house in Red Bluff, California listening to the stories that rolled from him. When he died this rocker went into the attic of the barn at our place in Paynes Creek and sat there for 20 years before my wife pulled it down and placed it in the house.

Now here in Colorado, I decided that my wife was right, it was time to restore this old rocker. It didn't creak when you sat in it, it was a little rough around the edges and gray from the break down of the lignin in the oak. I gently pulled on an arm which came up with no resistance...

Then I pulled a little on the post and the rail came away from the joint...

...then the whole chair fell apart on its own. From those years sitting in a barn attic the hide glue in all the joints failed from the moisture in the winter and the searing heat from the roof in the summer.

The first thing that I did was to use a card scraper to remove what was left of the patina and old finish to get back down to the original wood. That took several evenings after work to complete and then I attacked the old mortises and tenons to clean out the old glue and to make sure all joints fitted tight.

More on the restoration in Part 2!

Comments

Post a Comment